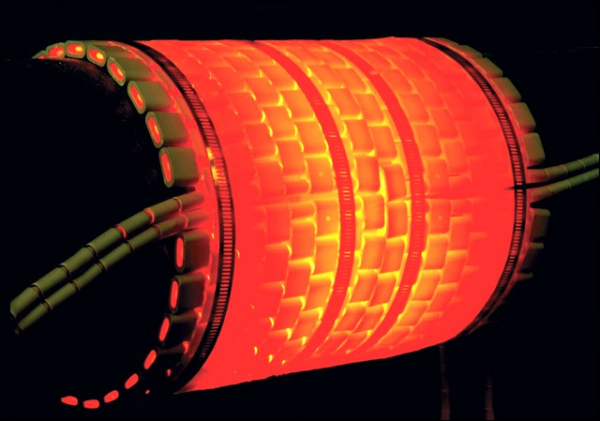

(click on thumbnail to enlarge) heat treat stress relieving special vessel fabricated from

monel, a high nickel-copper alloy selected for its corrosion, stress relieved by metlab. Stress relieving was done under a hydrogen-nitrogen atmosphere. Heat treat stress relieving | facilities heat treat stress relieving parts which have been heavily formed, machined, cut, or are fabricated by welding, have high internal stresses. The part or assembly can be made stress free by heating to a low temperature, where the stresses will be removed by thermal relaxation, without affecting the properties of the part. The resultant part will then be less prone to warp change dimensions during further processing or use.

The part or assembly can be made stress free by heating to a low temperature, where the stresses will be removed by thermal relaxation, without affecting the properties of the part. The resultant part will then be less prone to warp change dimensions during further processing or use.

This a36 steel weldment was stress relieved for a customer in the nuclear industry.

The weldment is a crane trolley frame which is used on an overhead bridge and is an example of our ability to treat large fabrications. It measures 40′ in length, 12′ in width, 10′ in height, and weighs 20 tons. Welding and other fabrication processes can cause high internal stresses within the finished structure. By heating the structure, those stresses are released without modifying any of the desired material properties. This weldment was heated to 1150°f and temperatures were maintained to within ±15°f during the heating period.

The weldment is a crane trolley frame which is used on an overhead bridge and is an example of our ability to treat large fabrications. It measures 40′ in length, 12′ in width, 10′ in height, and weighs 20 tons. Welding and other fabrication processes can cause high internal stresses within the finished structure. By heating the structure, those stresses are released without modifying any of the desired material properties. This weldment was heated to 1150°f and temperatures were maintained to within ±15°f during the heating period.

Welding, machining, milling, and cold working all induce stresses within materials. These stresses will cause unstable dimensional control downstream if not relieved thermally. Vacuum metal stress relieving is normally performed after rough machining, prior to final machining. Solar’s vacuum metal stress relieving produces bright, clean surface finishes, therefore often the part is stress relieved in a near net shape.